Artisan Denim

We source from the best!

We love and select high quality denim fabrics from Japan, because they are so robust that they will last longer than most people wear a garment in average. Don´t forget also that still today denim is a preferred and genuine material for workwear.

Japanese exellence

Amongst all high quality selvedge denim fabrics that are woven at mills around the world, it’s often said that Japanese denims are the best. This dates back to the 1960s, when giant American weaving mills switched from narrow 29”looms to more efficient 55” weaving machines. As the Americans phased out the laborious “old school” method of production, Japanese manufacturers purchased the old machines and continued to weave denim fabrics up to today. They have since combined traditional American weaving machine with typical Japanese production philosophy and methods to achieve highest quality standards:

- selection of the best yarns

- the most rigorous standards for dying

- perfect weaving

- the highest attention to artisan perfection

Upper Class Rough and Japanese excellence

Over the last 10 years we have selected 3 of the most reknowned denim producers of Japan. Our UC Rough series are exclusively made with denim from these 3 mills:

We believe that in order to craft the perfect pair of jeans, you need to start by having the best foundation. This is why UC ROUGH works with the finest, most sustainable Japanese denim mills in the world, to source the most premium materials and ensure its products are as perfect as they can be.

Kaihara Denim | カイハラ株式会社

rom No. 1 in Japan to the top manufacturer in the world. KAIHARA DENIM’s domestic market share is approximately 50%. It has been calculated that one out of …

Kurabo Denim | カイハラ株式会社

Founded in 1888, Kurabo is one of the few remaining cotton spinning companies in Japan today. We have been developing and producing denim products for over 40 years using our proprietary technologies in spinning, dying, weaving, and finishing Kurabo is committed to continuously improving and perfecting our products and services since our inception. This allows us to quickly identify needs in the denim market and resultantly provide products that go beyond our customers’ expectations.

No wonder Kurabo is a globally known denim mill and recognized as a leader in the world denim market.

PRIME BLUE

For nearly half a century, Kurabo has been supplying “Kurabo Denim” to leading brands around the world. In fact, Kurabo was the first company to make denim in Japan. And now, we have “Kurabo Denim Prime Blue” — a greater added-value in today’s diverse and competitive world of denim.

Kuroki Denim | トップ | クロキ株式会社

“KUROKI Co., Inc. continue to produce the highest of quality denims, with the world’s future in view, in Ibara, a city of pure water”! With this as our company motto, we will make every effort to deliver to our customers worldwide, a consistant quality of denim textile everyday.

Process 1 - Dyeing

Warp yarn dyeing process. Integration of traditional Bingo-mochi indigo dye technology with the modern rope dyeing technology. Deep indigo hue is attained by repeatedly emersing rope formed raw yarn in the indigo tank.

By leaving the core of the yarn undyed, “used” look is attained after the washing process.

The rich quantity and quality of the water makes the original KUROKI color.

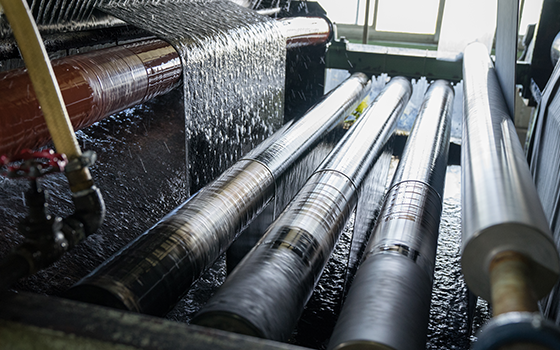

Process 2 - Weaving

Dyed and sized warp yarn is woven using the weft yarn. Various types of weaving machines from the state-of-the-art weaving machines to shuttle type weaving machines are installed, enabling us to weave various types of textile.

Stretch denim, selvage denim and other types of fabrics with special characteristics and uses are readily available for weaving with our machines. We also have machines installed for jacquard weaving.

Process III - Finishing

Final processing in production of the textile.Original fabric which went through mid way fabric inspection goes through singeing to smooth the surface, washing to control the texture of denim, skewing to prevent torsion and sanforizing for dimensional stability. Our products go through final fabric inspection after which they are packed for shipment.

Through this start-to-finish production, products that passed our quality standard are shipped to our customers.

We can control our production process depending on customers needs, requests and demands.

Coating and printing on the textile are readily available also.

No products in the cart.

No products in the cart.